State of the art Machinery

We have the most advanced stone-cutting factory in the Channel Islands!

Choosing the right machines from the best companies is important. We have excellent working relationships with our three main suppliers: Thibaut, Flow and Biesse.

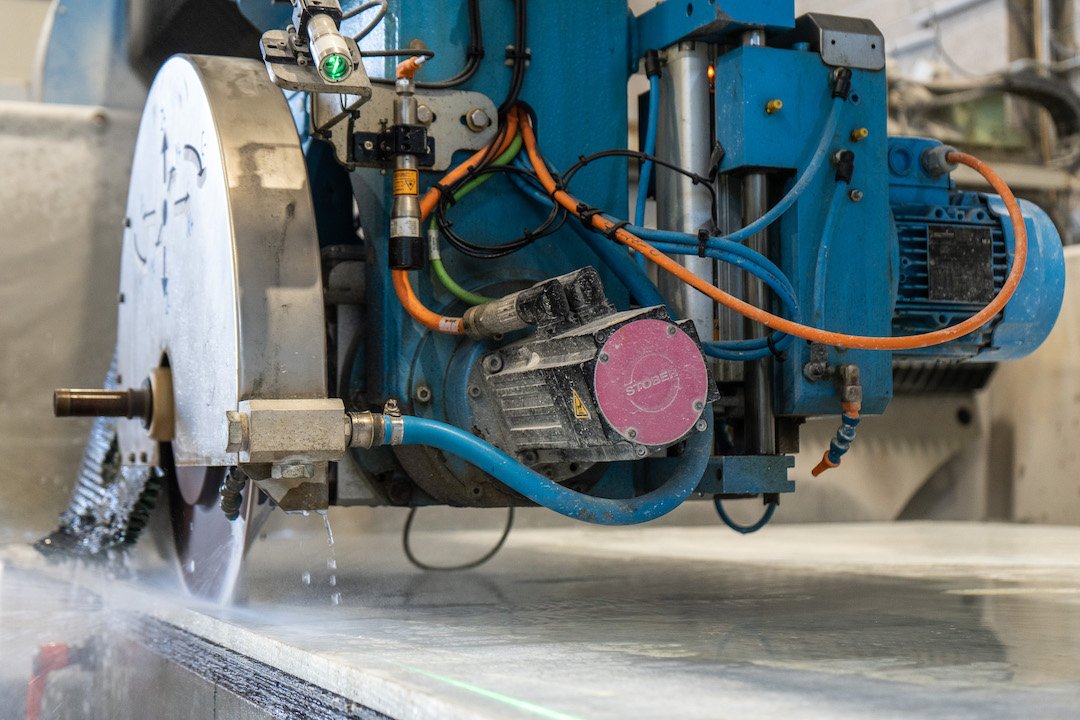

FLOW WATERJET

Cuts using a mix of ultrahigh-pressure water combined with garnet to create a clean cut.

Waterjet cutting technology can cut virtually any material, any shape, any thickness. – The only surfaces it can’t cut are reinforced glass and diamond.

The Mach 200 is specifically engineered to deliver value, reliability, and performance. Waterjet cutting is accurate with typical tolerances of 0.05mm and there is no heat distortion that can occur with laser cutting.

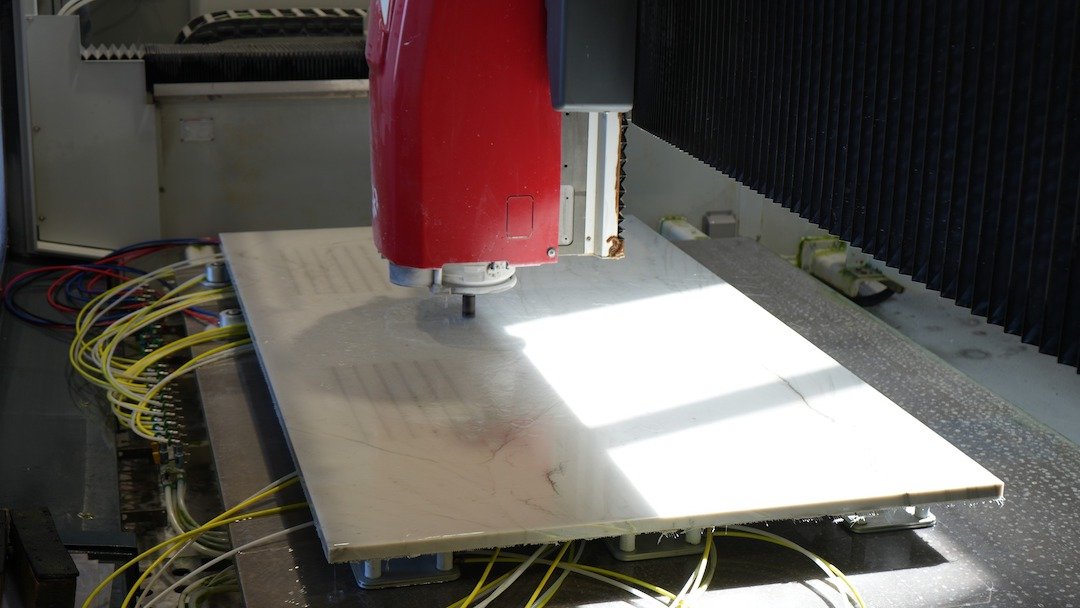

INTERMAC MASTER 38.3 CNC

The Master 38.3 is designed to deliver maximum flexibility and productivity for shops machining marble, natural stone, quartz and ceramic material.

It offers a greater tool change capacity and has a variety of options to accommodate all manufacturing requirements for countertops, vanities, fireplaces, sculpturing, flooring, facades and coverings, with the highest safety standards.

THIBAUT TC452

A true 5-axis numerically controlled monobloc sawing and shaping centre, the TC425 can automatically make cuts in any direction, or profile parts of any shape.

This saw was purchased in 2024 to compliment our existing portfolio of machinery as it was specially designed for cutting thin materials. It is superb, accurate and efficient for cutting Dekton® and Laminam® as well as mineral stone surfaces.

THIBAUT TC600

The TC600 CNC is a traditional sawing machine. It is a sturdy and heavy duty machine the continues to provide a reliable service.

This saw guarantees optimum and constant accuracy and cutting quality and is used to cut mineral and natural stone.

THIBAUT TC108S

The T108S V4 offers more than 25 functions on all types of material (granite, marble, concrete and mineral stone).

An upgrade in 2024 to replace an earlier version, this machine has a range of tools and the parameters to be able to mill, polish, drill, profile and saw.

Biesse 64 Faster edge POLISHER

A reliable and versatile edge polisher that guarantees brilliant edges, flawless results and short processing times.

This machine was another one that was added to the factory in 2024 as an upgrade to an older version.

The Edge Polisher runs using recycled water from our Dal Prete water recycling unit to ensure the best results whilst upholding environmental credentials.

KAESER HPC ASK 34T COMPRESSOR

The Kaeser compressor was installed in early 2024 ahead of the arrival of new cutting and polishing machines. It has a much larger capacity than our old compressor in order that all machines can run concurrently, and provides outstanding efficiency and reliability.

It is easy to maintain and the soundproofed housing reduces operational noise to a minimum. In addition it has an integrated dryer system installed to prevent moisture entering the holding tank.